• The single-board double-station filter channel can

work alternately, allow for quick screen changing and easy production &

maintenance.

• When the filter flashboard is in production and

reaches the predetermined pressure, the screen can be hydraulically changed.

• The flashboard filter channel has a split design to

ensure no dead angle. The filter area is more than one time of the ordinary

filter’s, contributing to a longer screen change interval. Fit for application

in the production of heat sensitive materials such as PVC which are prone to

buildup.

• With the help of hydraulic system, the slag on the

filter screen is quickly pushed out of the working position, the melt around

the filter screen hole is quickly cleaned and the filter screen on the ram is

replaced.

• Employ automatic adjustment sealing device to ensure

a sealing performance of 99%; Meet the requirement for high-output extrusion

production of any raw material, and can be used together with different

standard extruders.

• A preheating device is available to preheat the raw

material to the production temperature in advance, so that the product is not

affected by the cold material flow, contributing to higher product consistence.

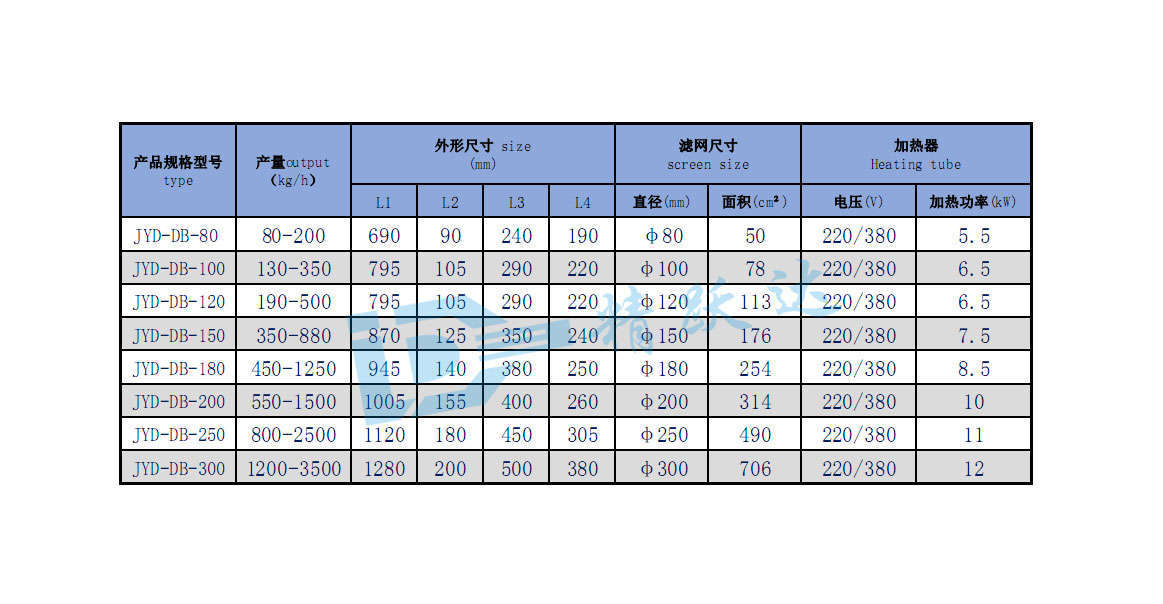

• The quick change time of single-board double-station

changer is ≤ 2 seconds, and the filter area is optional from ¢30mm to ¢350mm.

• High wear resistance, high pressure resistance, high

precision filter design, improved effective area and filtration quality.

• The performance will not be compromised under a

pressure between 25-30Mpa, and a temperature of about 300°C.

• The quick change time of single-board double-station

changer is ≤ 2 seconds, and the filter area is optional from ¢30mm to ¢350mm.

• The performance will not be compromised under a

pressure between 25-30Mpa, and a temperature of about 300°C.

Chrome

Chrome Firefox

Firefox IE8及以上

IE8及以上