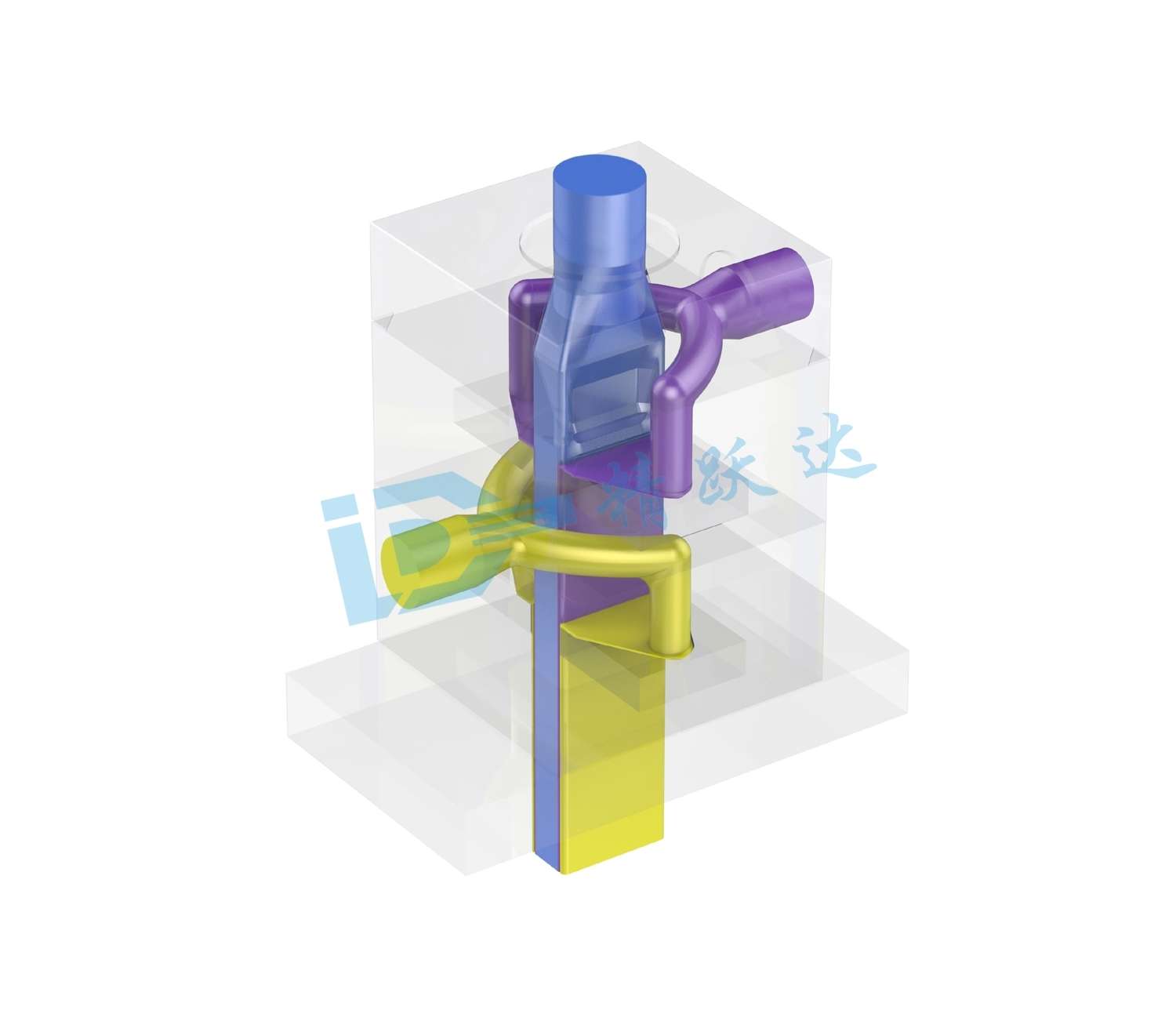

Insert Distributor

• The runner is designed on the detachable insert with

a streamline structure. Each detail is

controlled to improve the uniformity of the composite.

• The thickness ratio of the surface layer can be varied

freely by simply changing with a set of thick or thin inserts (or by changing the

core rod structure), resulting in quick switch between different compound

proportions.

• When changing the

number of composite layers, you can choose the

block

with the runner or the block without the runner according to the stratification

requirements to change the number of composite layers. The structure is simple,

and the runner is ensured no dead angle.

•The fasteners are made of 12.9 high-strength bolts.

Heating is set under control in zonal manner by high-quality stainless steel

heating rods.

• Customizable insulation to reduce heat loss and

minimize production costs.

• Combined die, simple in structure, easy to

disassemble and clean.

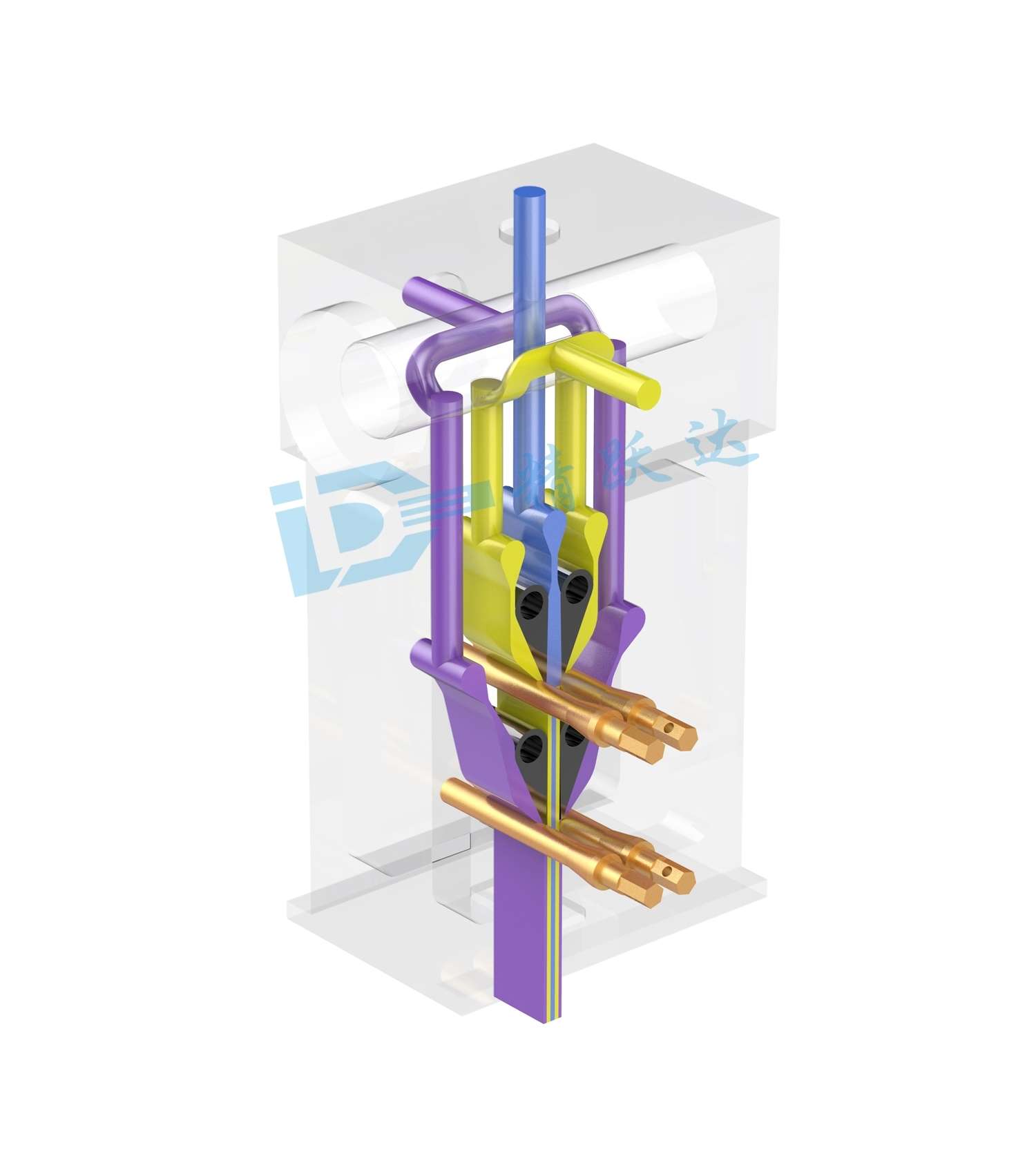

Pendulum Distributor

• The raw material is split in the core rod. Switching between different raw material

layers can be attained by a simple operation of changing the core rod.

• Adjust the core rod and pendulum on-line to attain

the desired compounding ratio of

different materials quickly and freely.

• The composite cavity is designed with an array of

pendulum to attain more layers

structure.

• Special internal runner design and high-precision

surface coating technology ensure the quality of extruded product to be

precisely controlled.

•The fasteners are made of 12.9 high-strength bolts.

Heating is set under control in zonal manner by high-quality stainless steel

heating rods.

• Customizable insulation to reduce heat loss and

minimize production costs.

• Combined die, simple in structure, easy to

disassemble and clean.

More products

• Insert type compound distributor, core rod type

compound distributor, pendulum type compound distributor, hollow compound

distributor, gradient color separation special compound distributor, etc.

Chrome

Chrome Firefox

Firefox IE8及以上

IE8及以上